Optimizing energy efficiency and machine performance is a priority for businesses in today's competitive landscape. If you're looking for effective solutions to improve your equipment's functionality, heat exchangers offer a compelling answer. These critical components facilitate the transfer of heat between fluids, significantly enhancing the efficiency of various systems.

By managing heat effectively, heat exchangers help reduce energy consumption and improve overall performance, leading to substantial cost savings over time. Whether you're involved in manufacturing, agriculture, or heavy-duty operations, understanding the role of heat exchangers is essential. Want to learn how they can elevate your operations? Read on to explore the advantages, types, and maintenance best practices associated with these indispensable systems.

What Are Heat Exchangers?

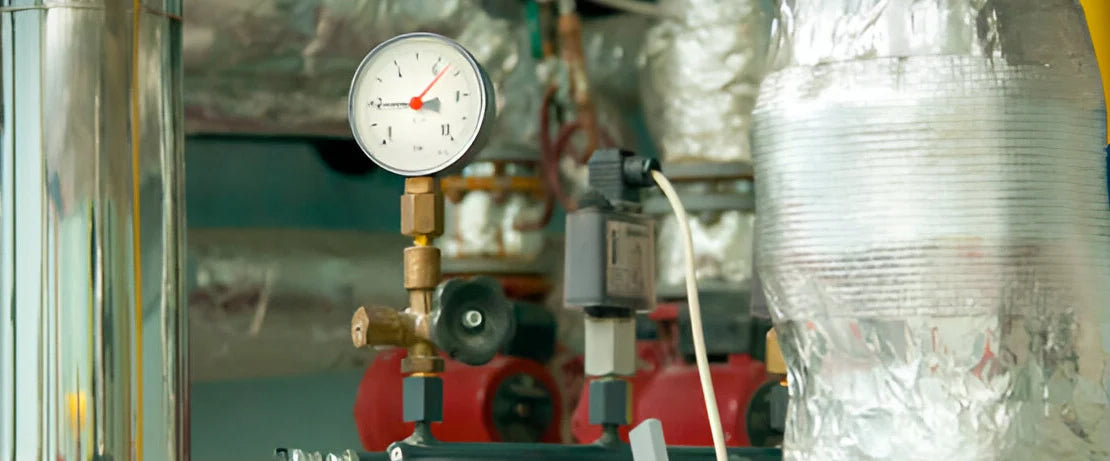

Heat exchangers are devices designed to transfer heat between two or more fluids while preventing them from mixing. These systems play a pivotal role in various applications, including heating, cooling, and energy recovery processes. Essentially, heat exchangers allow for efficient thermal management, making them vital in many industries.

There are several types of heat exchangers, each suited for specific applications. For example, an air-to-water heat exchanger transfers heat from air to water, commonly used in HVAC systems to provide heating or cooling. Another example is the boiler heat exchanger, which facilitates heat transfer from the combustion gases to the water in the boiler, ensuring optimal heating performance.

Future trends in the heat exchanger industry include the use of advanced materials like high-performance alloys for improved efficiency and durability. The rise of IoT technology will enable smart heat exchangers with real-time monitoring and predictive maintenance. Sustainability is also a key focus, driving designs that reduce energy consumption and waste. Furthermore, innovations are leading to more compact and lightweight heat exchangers, which are ideal for modern machinery.

The Role of Heat Exchangers in Machine Performance

Heat exchangers are indispensable components in a wide array of machines, significantly influencing their efficiency and overall performance. By facilitating the transfer of heat between different fluids, these systems help maintain optimal operational temperatures, which is vital for preventing overheating and its associated costs. A deeper understanding of the role heat exchangers play in machine performance can empower businesses to make informed decisions about their equipment and maintenance strategies.

- Temperature Regulation: Heat exchangers help maintain ideal temperature ranges in machinery, which is essential for consistent performance. They prevent overheating that could lead to equipment failure.

- Enhanced Equipment Lifespan: By managing thermal conditions, heat exchangers reduce wear and tear on machinery, contributing to a longer operational lifespan and fewer repair costs.

- Efficiency in Industrial Applications: In settings such as manufacturing and HVAC systems, air-to-water heat exchangers provide effective cooling solutions that enhance overall machine productivity.

- Importance of Maintenance: Regular cleaning and inspection of heat exchangers are crucial for ensuring smooth fluid flow and preventing waste buildup. This proactive approach optimizes performance and extends the lifespan of the equipment.

- Diverse Applications: From boilers to air conditioning systems, heat exchangers are integral to various industries, helping them operate efficiently under varying conditions. Understanding their role can lead to better energy management strategies.

Types of Heat Exchangers

Heat exchangers are vital components in a wide range of industrial applications, enabling efficient heat transfer between fluids. Understanding the different types of heat exchangers and their specific applications is essential for optimizing energy efficiency in various systems. Below, we explore three common types of heat exchangers: shell-and-tube, plate, and finned-tube exchangers.

Shell-and-Tube Heat Exchangers

Shell-and-tube heat exchangers consist of a series of tubes, one set containing the hot fluid and the other the cold fluid. The tubes are enclosed in a cylindrical shell, which facilitates heat transfer between the two fluids as they flow in opposite directions. This design allows for effective heat exchange while maintaining separation between the fluids.

Plate Heat Exchangers

Plate heat exchangers utilize thin, corrugated plates stacked together to create multiple channels for fluid flow. The hot and cold fluids flow in alternate channels, allowing for efficient heat transfer across the plates. This design maximizes the surface area for heat exchange while minimizing the space required.

Finned-Tube Heat Exchangers

Finned-tube heat exchangers feature tubes with extended surfaces, or fins, which increase the surface area available for heat transfer. The fins enhance heat exchange between the fluid inside the tubes and the surrounding air or another fluid. This design is particularly effective for applications where air is the cooling medium.

Elevate Your Efficiency with Dolphin Heat Exchanger USA, INC

As we've explored, the significant impact of heat exchangers on machine energy efficiency and performance is clear. By embracing advanced heat transfer solutions, businesses can enhance operational effectiveness and achieve substantial energy savings.

At Dolphin Heat Exchanger USA, we specialize in delivering innovative products tailored to meet the specific needs of various industries. Our extensive range of heat exchangers, including air-to-water and high-flow options, is meticulously designed to enhance the thermal management of various systems. By maximizing heat transfer efficiency, our products help reduce energy consumption, leading to lower operational costs and improved overall performance.

Moreover, our focus on bespoke solutions means that we cater to the specific needs of different industries, from heavy-duty trucks to agricultural machinery. Each unit is crafted to optimize cooling and heating processes, ensuring that equipment operates at peak efficiency.

Dolphin Heat Exchanger USA, INC is committed to sustainability as well. By enabling energy savings and reducing waste, our heat exchangers not only contribute to enhanced performance but also support environmentally friendly practices. With over 38 years of experience in the field, we continue to set industry standards, delivering solutions that not only meet but exceed customer expectations.

We understand the critical role that efficient heat exchangers play in your operations, and our commitment to quality and customer satisfaction sets us apart. If you have questions about how our solutions can benefit your business, please don’t hesitate to reach out. You can contact us at +1 (844) 536-5744 or via email at info@dolphinradiator.com. Let us help you elevate your energy efficiency and performance today!